|

We have with us a brand new Makino F3 CNC VMC, Singapore make, specially designed for Die/Mold machining.

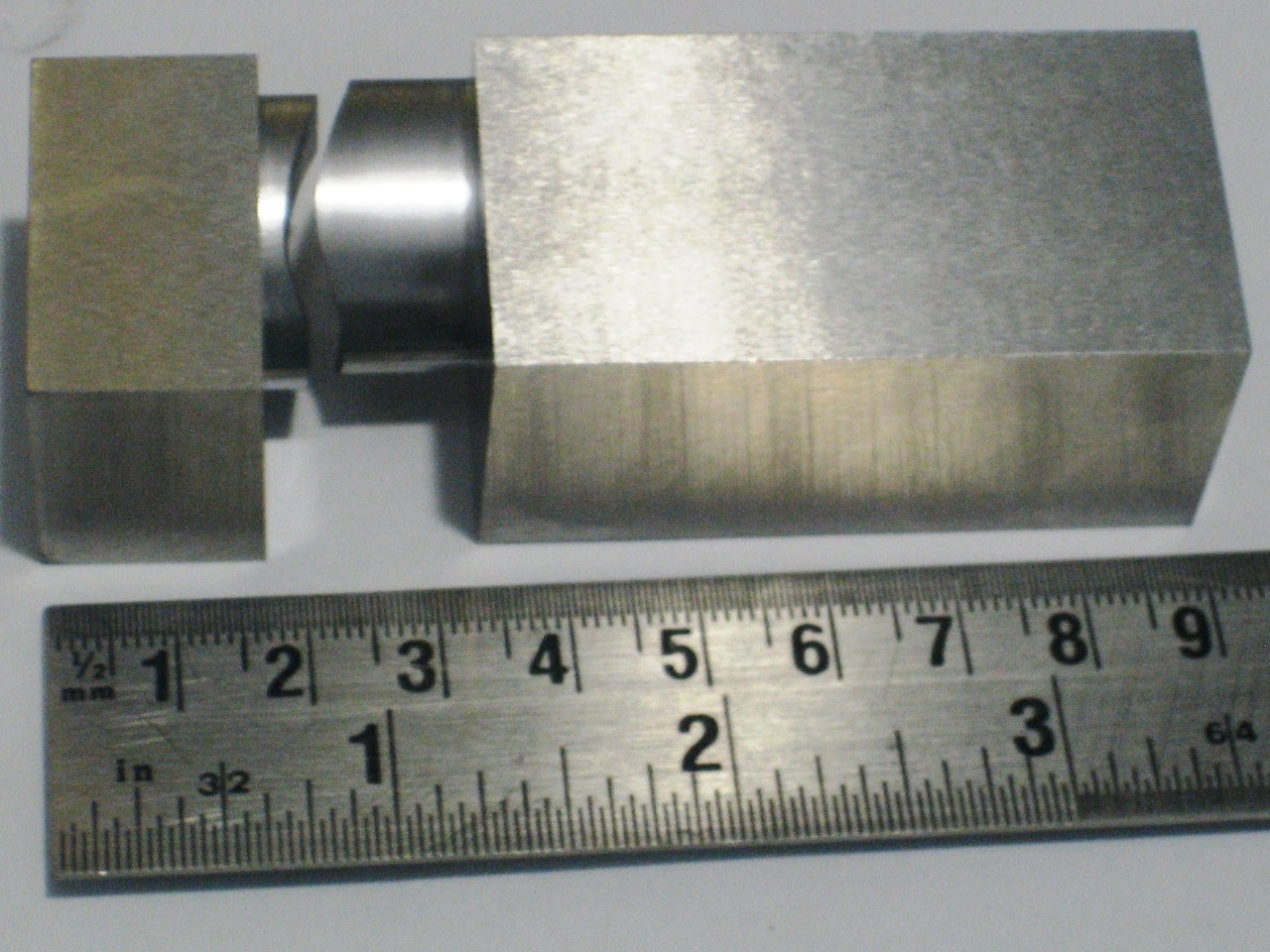

The machine is very accurate with +/-2.5 microns accuracy, 12000 rpm spindle with a 22kW motor & very sturdy with 8 tons weight.

The X,Y,Z travels of the machine are 650x500x450mm. The machine bed can take dies up to 850x500mm in size and up to 800kgs in weight.

With this machine we can take up hard-part machining up to 70HRC.

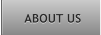

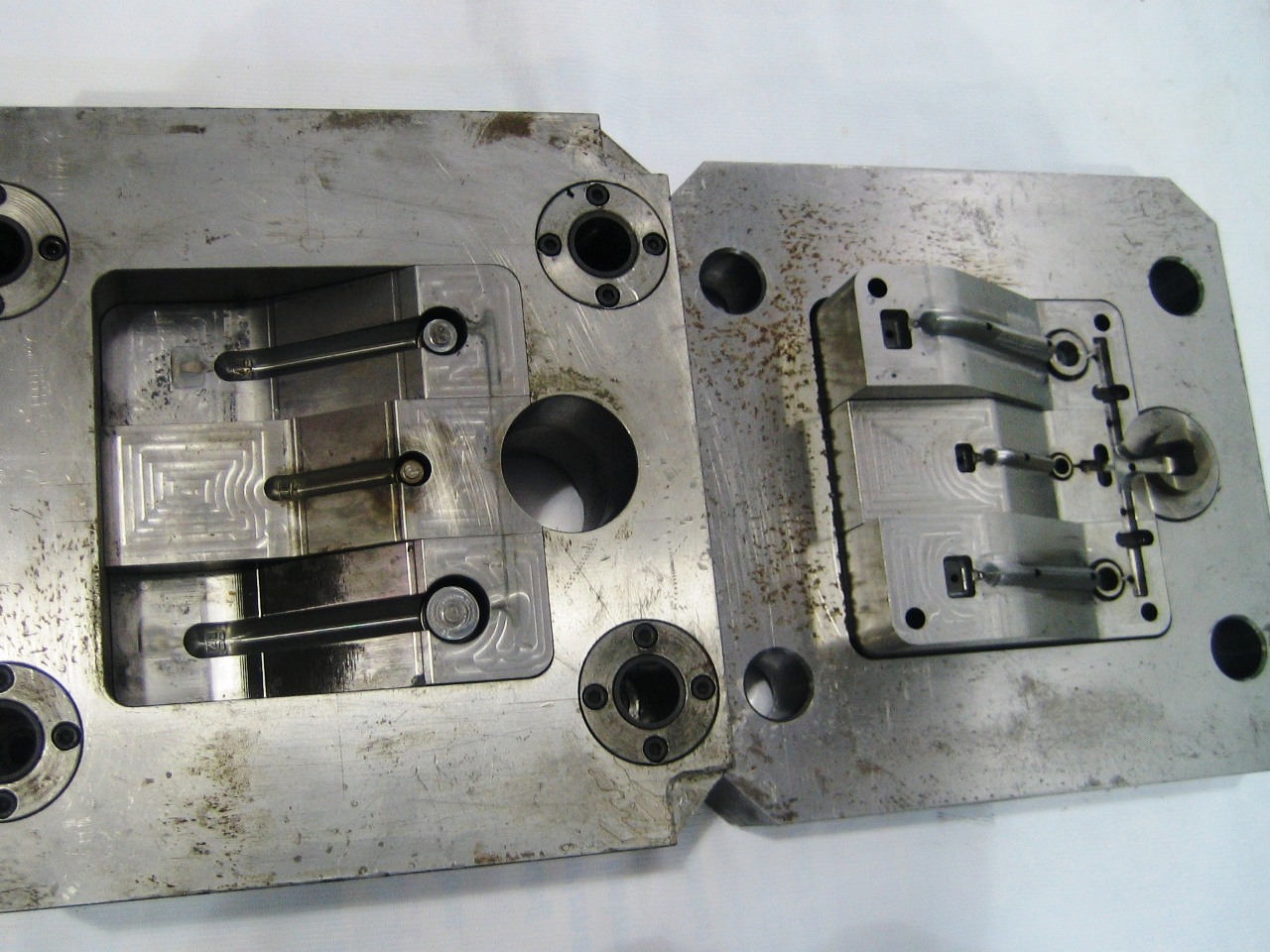

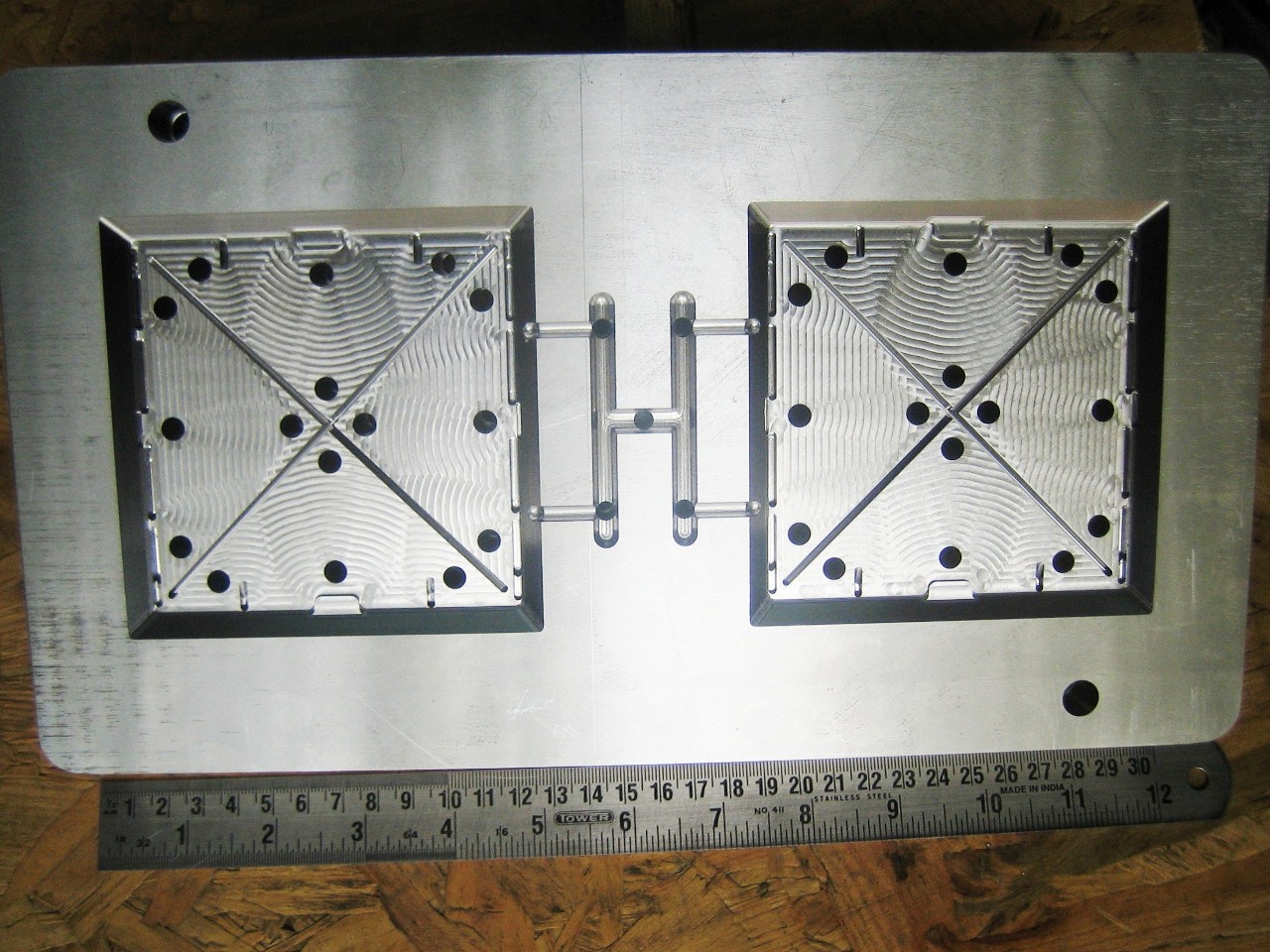

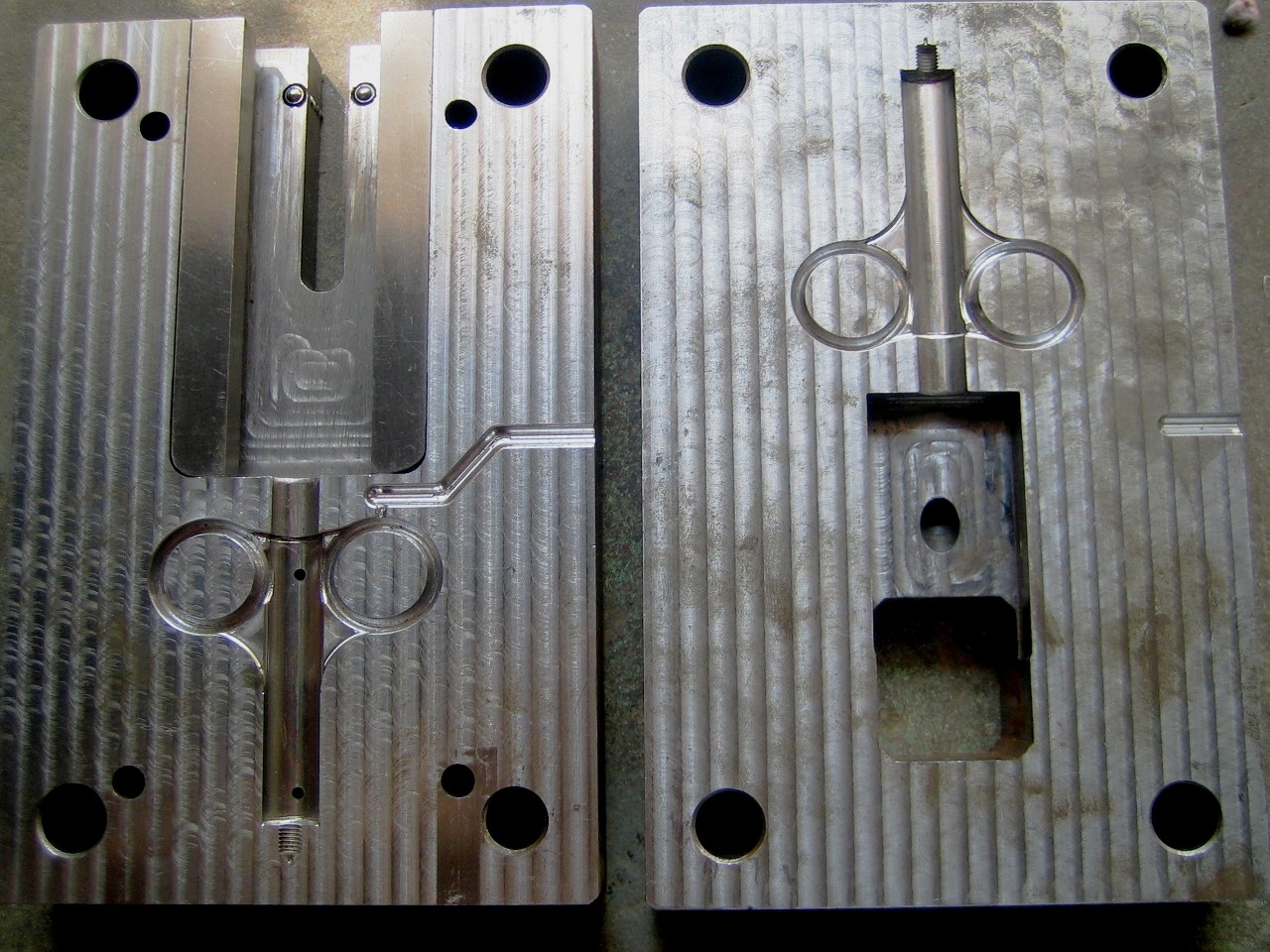

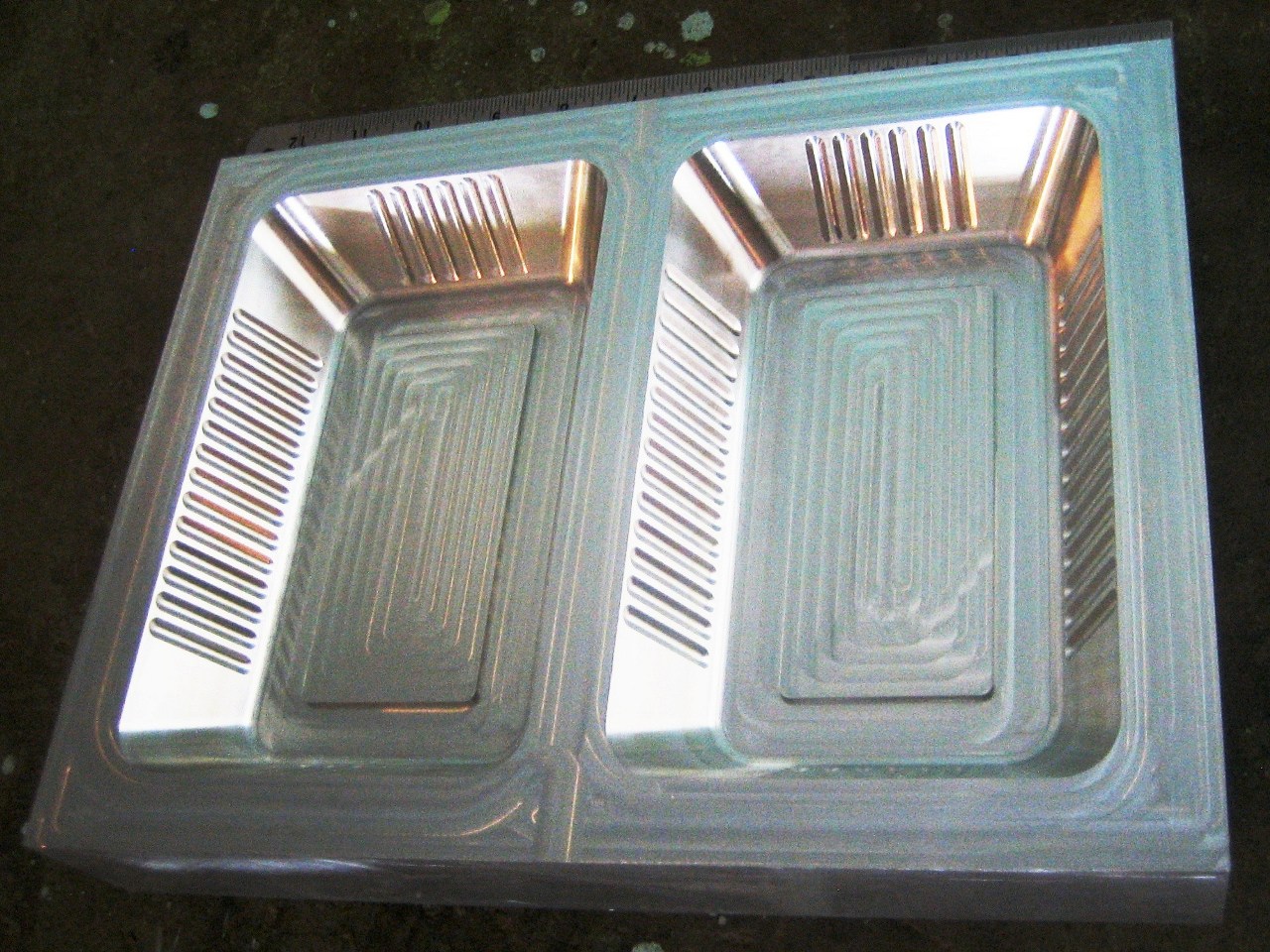

We can take up manufacture of the following die/molds to very high accuracy, quick delivery and highest quality standards.

We have gained invaluable expertise in core cavity machining of dies/molds and are ready to take up any challenging job work. With our focus on quality and on-time delivery, we have acquired many repeat customers like Gearock Forge, Sansera Engineering, Sundaram Auto Components, Seeaar Machine Tools, Fujiyama Mould Tech, Konar Engineering, Akme Technologies, Suveswaru Enterprises to name a few. For Piston dies and Pressure Die Casting dies, we offer our customers an end-to-end solution starting from component design -> die design -> die manufacture -> component trials |